Project Description

Oxford Corridor Project

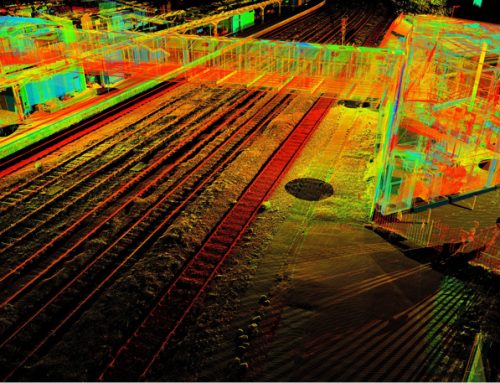

The Oxford Corridor is a site of extensive capacity and performance investment in the railway network.

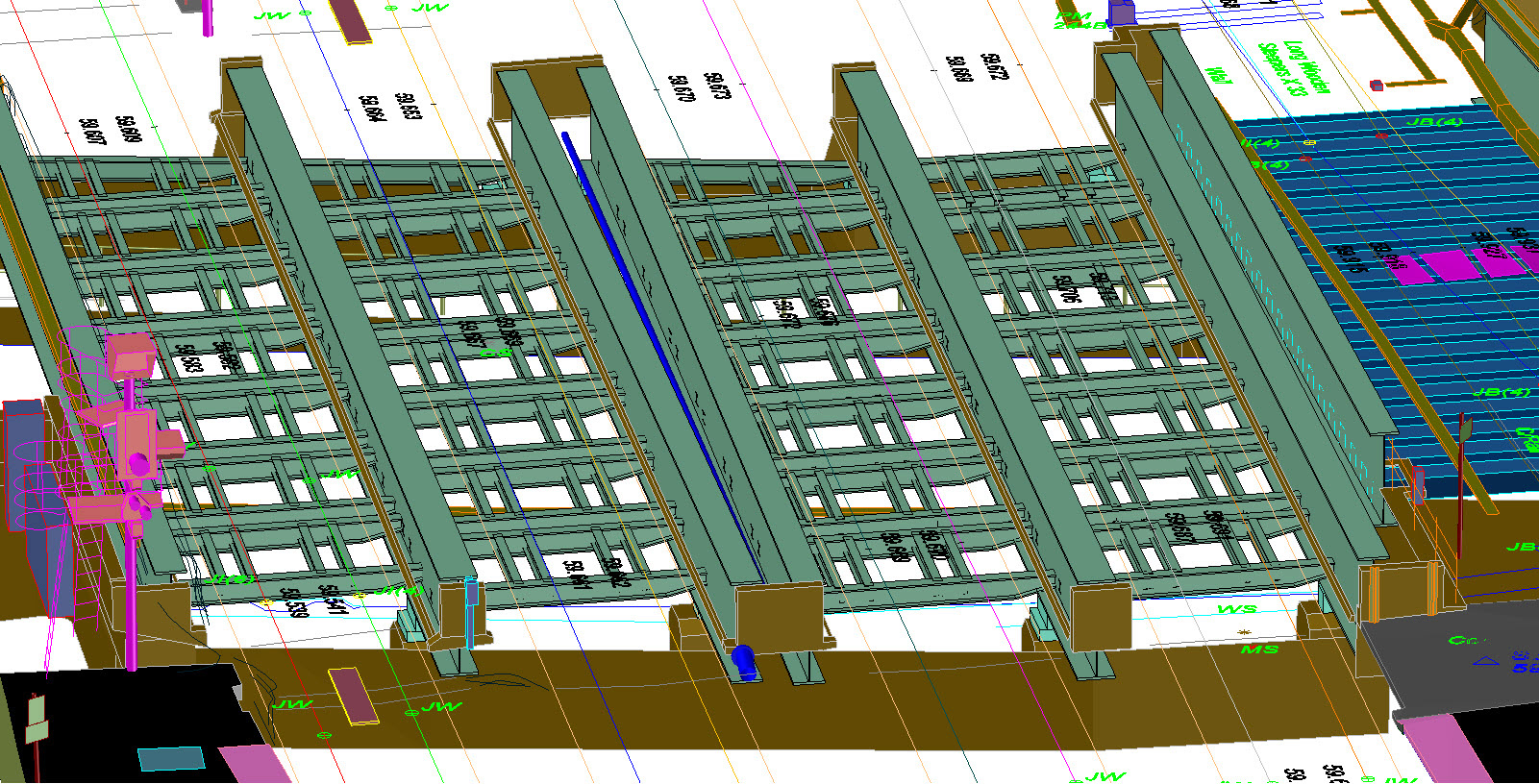

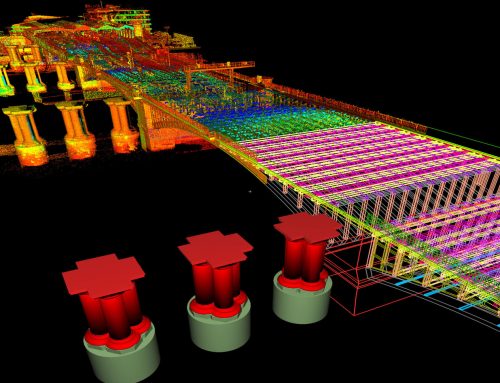

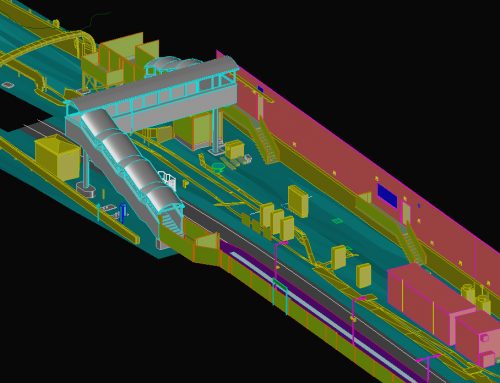

In 2014 ABA was contracted by TATA Steel to survey Oxford Station, its surrounding roads and buildings and the railway corridor extending approximately 5 km to the north and 2 km to the south. The deliverables included a highly accurate fully surfaced 3D wireframe CAD model which was compliant to various BIM levels of detail depending on the client’s requirements in particular areas.

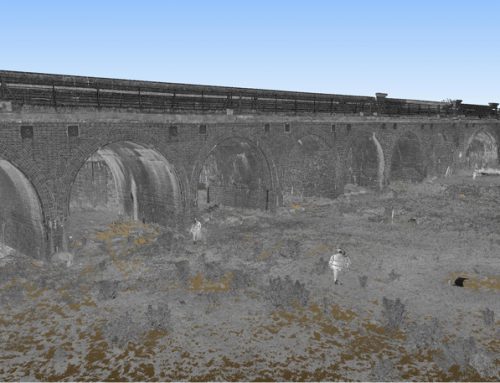

This incorporated; railway permanent way, level crossings, under and over bridges, station buildings and infrastructure, an area of town centre with historic buildings and highway detail, subways, confined spaces and sub surface services.

The deliverables had to satisfy the requirements of many disciplines, including; track, OLE, signals, drainage, civils and M&E.

A network of survey control was established using GNSS which was then traversed and levelled.

Railway tracks were surveyed using Total Station and railshoe. The whole route was pushed using GRP Rail trolleys to provide kinematic scan data for clearance purposes and static scanned to provide a registered point cloud. The point cloud was used to extract detail for the 3D model using Leica Cyclone.

The route was also flown to provide aerial photography of areas inaccessible to the surveyors at trackside (e.g. topographical features more than 3m off-track up to the boundary fence, which is especially difficult in cuttings and embankments) and the data then being extracted using photogrammetry.

The survey was undertaken over the course of 12 months using ABA’s team of surveyors, all PTS certificated and Confined Space trained. All senior surveyors are also COSS certificated.

ABA’s planning team worked closely with the client in planning and coordinating access, possessions and line blockages. There were also weekly debrief and planning meetings.

Over 1600 static scans were captured using ABA’s Leica HDS 6200 laser scanners. This was processed in 1TB of Cyclone Databases. 78GB of raw kinematic scan data was also recorded using the GRP rail trolleys.

In addition to the 3D model and gauging data we supplied Truview and POD files to the client so that their engineers could view and access the raw point cloud data.